What Does the Future of Wire Bending Look Like?

Wire components quietly support much of modern infrastructure. From storage systems in warehouses to equipment enclosures in technical facilities, precision metal structures make daily operations possible. As demand grows for stronger, lighter, and more consistent assemblies, wire bending continues to evolve.

Advances in automation, tooling accuracy, and integrated production methods are reshaping what manufacturers can expect from formed wire parts. Industries that rely on server racks and industrial material racks need consistent dimensions, repeatable strength, and scalable output. At the same time, fabrication methods such as MIG welding and TIG welding remain essential for structural integrity and specialty assemblies.

The future of wire bending is not about replacing core processes. It is about refining them to deliver tighter tolerances, greater efficiency, and improved long-term performance.

What We’ll Cover:

- Automation and precision in modern wire bending

- Stronger rack systems through smarter design

- The role of MIG welding and TIG welding in the future

- Applications driving the next generation of wire bending

- Scalability, consistency, and manufacturing partnerships

- Key takeaways

- About Wirefab

Automation and Precision in Modern Wire Bending

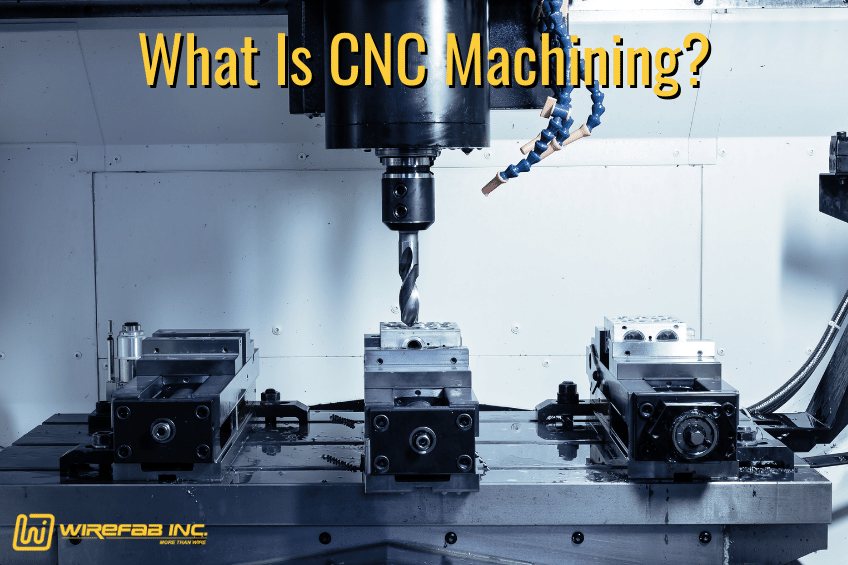

Modern wire bending relies heavily on CNC-controlled equipment that delivers repeatable accuracy across production runs. Automated bending machines reduce variability while increasing throughput. That translates to fewer adjustments between batches and more consistent parts across high-volume programs.

Precision is critical in load-bearing applications. For example, industrial material racks must maintain shelf alignment under weight. Even minor deviations in bends can affect structural performance. Advanced bending systems control angle, radius, and wire positioning to meet demanding tolerances.

Automation also improves efficiency. Instead of relying on manual adjustments, manufacturers can program complex geometries into production sequences. This development reduces waste and shortens lead times. For operations producing components for server racks, consistent spacing and alignment directly support airflow management and equipment fit.

As automation continues to improve, wire bending will support larger production volumes without sacrificing dimensional control.

Stronger Rack Systems Through Smarter Design

The future of rack systems depends on smarter structural design. Rather than adding excess material for strength, modern engineering focuses on distributing load efficiently. Well-designed industrial material racks use strategic bends, reinforcement points, and cross supports to maximize performance without unnecessary weight.

In technical environments, airflow and access are just as important as strength. Properly engineered server racks use open construction to promote cooling while maintaining rigidity. Wire-based structures help balance airflow with structural support, allowing components to remain accessible for maintenance.

Improved wire bending techniques make these optimized designs possible. Complex forms that once required multiple welded parts can now be produced in fewer pieces with consistent geometry. This streamlines assembly and reduces potential weak points.

As infrastructure grows in scale and complexity, rack systems must deliver durability, accessibility, and predictable performance across installations.

Find the right wire-forming capabilities for your next manufacturing project

The Role of MIG Welding and TIG Welding in the Future

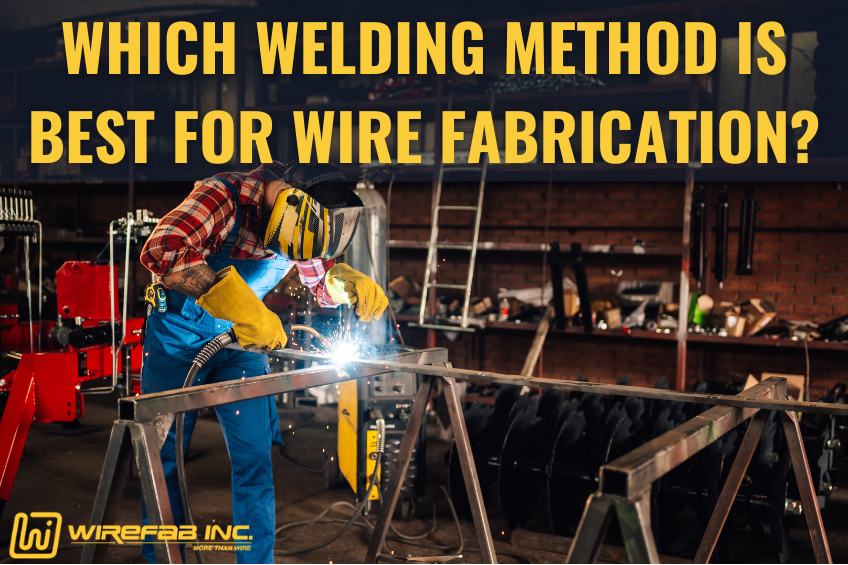

While bending technology continues to advance, welding remains essential for final assembly. Automated forming shapes the structure, but MIG welding and TIG welding secure connections and reinforce stress points.

MIG welding is often preferred for structural joints and thicker materials. It provides strong, reliable connections suited for industrial material racks and heavy-duty frames. For high-volume production, MIG welding supports speed without compromising structural stability.

TIG welding offers greater control and is frequently used where appearance or precision is critical. In visible components or specialty assemblies connected to server racks, TIG welding helps maintain clean lines and controlled heat input.

As wire bending systems grow more advanced, welding processes are increasingly integrated into streamlined workflows. The future is not about replacing MIG welding or TIG welding. It is about coordinating bending and welding processes to maintain consistency and reduce production variability.

Together, these fabrication methods ensure rack systems and structural components perform reliably in real-world environments.

Applications Driving the Next Generation of Wire Bending

Industry growth continues to shape how wire components are designed and manufactured. Data centers, distribution facilities, and manufacturing operations are expanding rapidly. This growth increases demand for durable server racks and high-capacity industrial material racks.

In data centers, airflow, cable routing, and structural alignment all depend on accurate wire bending. Even minor inconsistencies can affect installation speed and system performance. Precision matters when racks must align across rows or integrate into existing infrastructure.

Warehouse and logistics operations place heavy loads on storage systems. Industrial material racks must handle repeated movement, pallet transfers, and fluctuating inventory levels. The ability to produce consistent bends and reinforcement points allows these racks to withstand daily use.

Outside of racks, equipment frames, guards, carts, and specialty fixtures also benefit from improved wire bending accuracy. As applications become more specialized, manufacturers need flexible production methods that can adapt to custom requirements without sacrificing repeatability.

Save time and money on all of your wire-bending needs!

Scalability, Consistency, and Manufacturing Partnerships

The future of wire bending also depends on scalability. Manufacturers often need to move from prototype runs to large production volumes quickly. That transition requires consistent tooling, integrated welding, and coordinated scheduling.

Programs involving server racks or large orders of industrial material racks demand predictable output. Consistency across multiple facilities or rollouts reduces installation delays and performance issues. Integrated bending, MIG welding, and TIG welding processes allow production to scale while maintaining dimensional control.

Working with an experienced fabrication partner ensures that automation, forming accuracy, and welding precision operate within a controlled environment. This structure supports steady growth without increasing risk.

As demand rises across industrial and technical sectors, scalable wire bending programs will remain essential for manufacturers seeking long-term stability.

Key Takeaways

- Wire bending continues to advance through automation, improving precision and repeatability.

- Modern rack systems benefit from optimized designs that strengthen industrial material racks without adding unnecessary weight.

- Growth in data centers increases demand for durable, airflow-focused server racks.

- Both MIG welding and TIG welding remain critical for structural stability and finish control.

- Coordinated bending and welding processes support scalable production and consistent performance.

100% U.S.-Based Industrial Wire Bending

If your business depends on high-performance racks or precision-formed components, you need a manufacturing partner that understands the full production process. Wirefab combines advanced wire bending, integrated MIG welding and TIG welding, and large-scale manufacturing capabilities to support projects across industrial and technical markets. Whether you are producing server racks, industrial material racks, or specialized structural assemblies, Wirefab delivers consistent results at scale. Contact our team to discuss your next program and see how our expertise can support your production goals.

Wirefab Inc. has over 65 years of experience in custom sheet metal fabrication. Whether you need custom CNC machining, laser metal cutting, or material handling carts, we’re here to help. Above all, we’re always eager to solve our customers’ problems with a broad range of manufacturing capabilities. Contact us today to see how we can simplify your next project.

You can also follow us on Instagram to view our custom wire products!