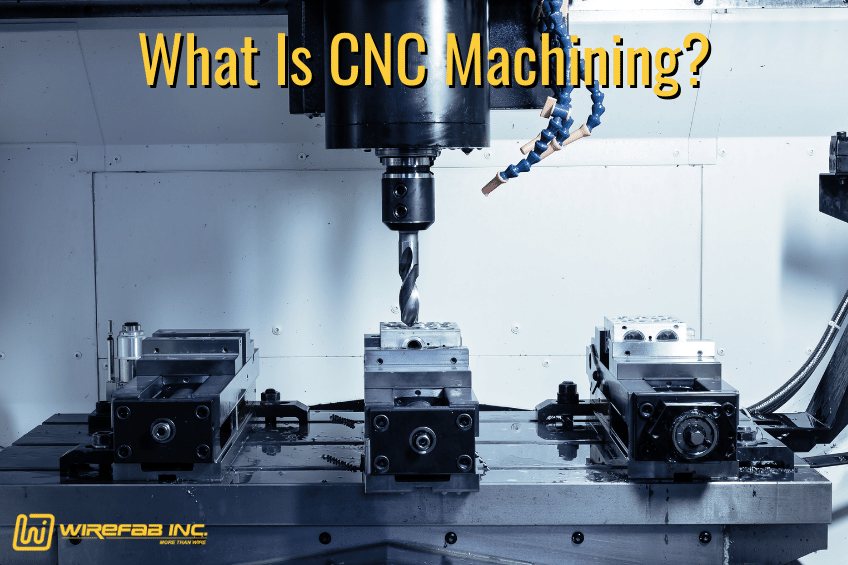

What Is CNC Machining?

With the tremendous technological growth, CNC machining has far exceeded what we can accomplish with manual operation. It has elevated what metal fabricators can build with levers, screws, and buttons. The advent of CNC machining has also rendered excellent control and comfort to machine operators. By using CNC machining, manufacturers can more easily fabricate parts around the globe.

What Is a CNC Machine?

CNC stands for Computer Numerical Control. The process drives metal and tube fabrication with increased automation, productivity, and versatility.

The primary component of CNC machining includes a command function, a drive or a motion system, and a feedback system. In other words, a CNC machine utilizes a computer-driven machine tool to manufacture a part of solid material in a customized shape.

HOW DO YOU SET UP A CNC MACHINE?

The inner mechanisms of a CNC machine rely on digital instructions, usually fed on computer-aided manufacturing or computer-aided design software like SolidWorks. Most companies that specialize in contract manufacturing utilize some form of these machines.

Operation

Firstly, operating a CNC machine involves an engineer making a design on software and then transferring it to a CNC fab programmer.

Design

Secondly, after moving the design, the programmer opens the file in the Computer-Aided Manufacturing program to select the tools required to execute the NC program for the CNC. The programmer then sends the NC program to the CNC machine and gives an operator a list of appropriate tooling setups.

Looking for CNC Machining & METAL FABRICATION Services?

Fabrication

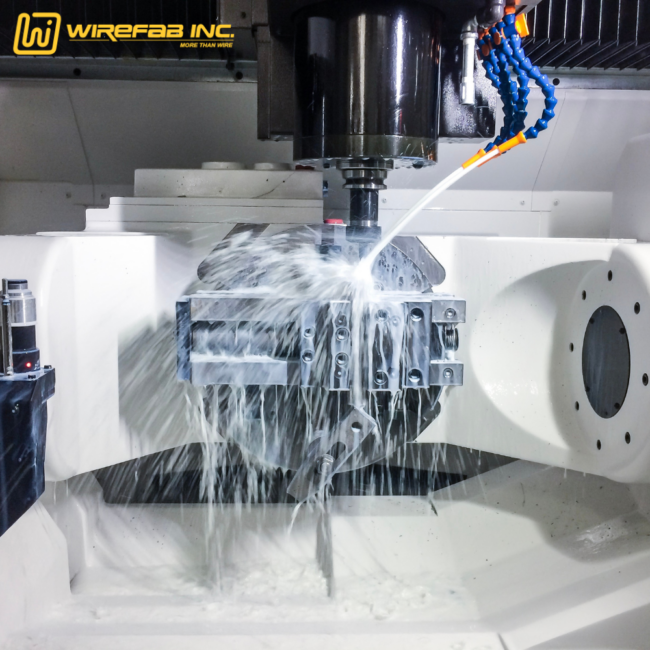

Thirdly, the operator loads the tools and raw materials. They also verify whether the machine makes parts according to the requisite customization and specifications by running sample pieces and measuring them.

Generally, the setup operator renders the first article piece to the concerned department that approves the quality of the material. The department ensures that the dimensions of the material meet your requirements.

Production

Finally, the CNC machine is loaded with sufficient raw materials to make custom metallic materials. During the whole procedure, a machine operator scrutinizes the working of the machinery to ensure that it is smoothly functioning, loaded with adequate raw materials and producing the custom metals as per the specifications.

HOW TO FIND THE RIGHT CNC MACHINE FOR YOU

CNC services typically operate with two types of software: Computer-Aided Drawings and Computer-Aided Manufacturing.

Computer-Aided Drawing (CAD)

For entry-level CNC machining, manufacturers employ CAD software for designing parts. Many CAD software programs on the market allow you to create designs with custom specifications. The most popular CAD programs include AutoCAD, Rhino3D, and SolidWorks.

Today, there are also many cloud-based CAD solutions available. Many CAD programs also allow integrating designs with CAM. Otherwise, you need to transfer the file from CAD to CAM.

Computer-Aided Manufacturing (CAM)

The main distinction between CAD and CAM software is that CAM allows you to establish a “job tree.” This job tree lets you customize your workflow, tool paths, and cutting simulations before fabrication begins.

CAM software serves as an addition to CAD software. It generates g-codes that regulate the movements and speed of CNC tools and raw materials and directs them where to go. The wizards in CAM software make it convenient to program a CNC machine. Some of the most sought-after CAM programs include Mastercam, Edgecam, and Solidcam.

We have 300+ machines to meet your manufacturing quota.

Types of CNC Machines

There are countless CNC machines on the market today. If your focus is sheet metal fabrication, custom CNC services can help you cut or move materials as directed on the controller. Similarly, these machines can also pick up and pass materials like sheet metal in an assembly line.

Let’s examine some of the more common types of CNC machines below.

Lathes

Lathes turn the workpiece and transfer the cutting tool to the workpiece. Primary lathes consist of a 2-axis, but adding more axes to the lathes doubles the complexity of the cutting procedure. Typically, lathes make symmetrical shapes like spheres, cones, or cylinders.

Routers

CNC routers have a striking resemblance to CNC milling machines. For instance, the only difference lies with the suitable materials for cutting. Routers are well-suited for cutting softer materials, not metals. They are ideal for those materials which do not require higher accuracy. Moreover, the reason behind this lower accuracy is lower power output. However, routers are incredibly fast in their function and produce parts at a breakneck pace.

Milling

Unlike manual milling, which uses handwheels or screws to cut a metallic piece, a CNC fab mill uses highly accurate ball screws to the precise coordinates. Overall, milling CNC machines may vary in size and work on various axes.

Grinding

A CNC grinding machine employs a rotating grinding wheel to remove material. After that, the ultimate goal of a grinding machine is to render a high-end precision finish to a custom metal display.

Plasma Cutters

In CNC plasma cutting, a powerful laser cuts and fabricates metal. Plasma cutters cut pre-programmed designs and shapes, like custom metal displays or POP wire.

3D Printers

A 3D printer uses programs that direct the small pieces to make the custom shape. Usually, a laser solidifies the liquid contents as the layer grows. As a result, this layer-to-layer formation of 3D parts makes contract manufacturing considerably easier.

How CNC Machines Can Save You Time and Money

The automation aspect of CNC machines means they can operate continuously without the fatigue and inconsistencies associated with human operators. This leads to increased production capacity and faster turnaround times, enabling manufacturers to meet client demands more efficiently.

Moreover, CNC machines can quickly switch between different tasks and setups, which reduces the downtime that typically comes with reconfiguring manual machinery for different production runs. This flexibility is particularly valuable in today’s market, where customization and rapid response to changing consumer demands are crucial.

From a cost perspective, although the initial investment in CNC machinery can be substantial, the long-term savings are significant. The need for manual labor is drastically reduced, not just in the quantity of labor but also in the skill level required. A single operator can oversee multiple CNC machines, each performing complex tasks independently.

This reduction in labor costs, combined with the decrease in material waste and the ability to operate around the clock, makes CNC machines a cost-effective solution for manufacturers looking to optimize their operations. Additionally, the precision and consistency of CNC machines mean fewer errors and defects, leading to savings in quality control and reducing the cost associated with returns or rework.

Key Takeaways

Today, CNC machines can enhance efficiency in aerospace, defense, electronics, mining, the food industry, automotive, product designing, sheet metal fabrication, press brakes, and more.

Modern CNC machining is adept at transforming sheet metal into complex designs. You can program CNC services to function rapidly with incredible repetition through automation. Custom CNC machining can automate your process according to your allotted time, resources, and specifications. Automating CNC machinery enhances the quality and accuracy of your contract manufacturing process.